Flywheel Energy Storage

Global decarbonisation requires green energy storage solutions, of which flywheels have been touted as one of its principal proponents.

These clever yet simple mechanical systems are certainly part of the energy storage future, just perhaps not in the way you envisage.

Read on to find out why!

Contents

- Renewables need storage

- Energy storage is growing

- What is a flywheel?

- Flywheel Energy Storage (FES)

- The merits of flywheels

- The downside of flywheels

- Conclusion

- External Resources

Renewables need storage

We’re in the midst of a global energy transition. The rollout of renewables is accelerating rapidly as governments are under increasing pressure to decarbonise.

Wind energy and solar energy are the most rapidly growing types of renewables, but their fluctuating power output is a headache for electricity grid operators.

This fickleness in power output is one of the main arguments used to discredit renewables. They cannot produce energy when we need it, and the daily variations are significant, leading to rising business electricity prices.

Unfortunately, most places like the UK rely on fossil fuel power plants to ramp up production to meet demand, as large-scale green electricity storage is simply not yet available.

This would enable these variable renewables to store energy when demand is low and release it back into the grid when demand is high.

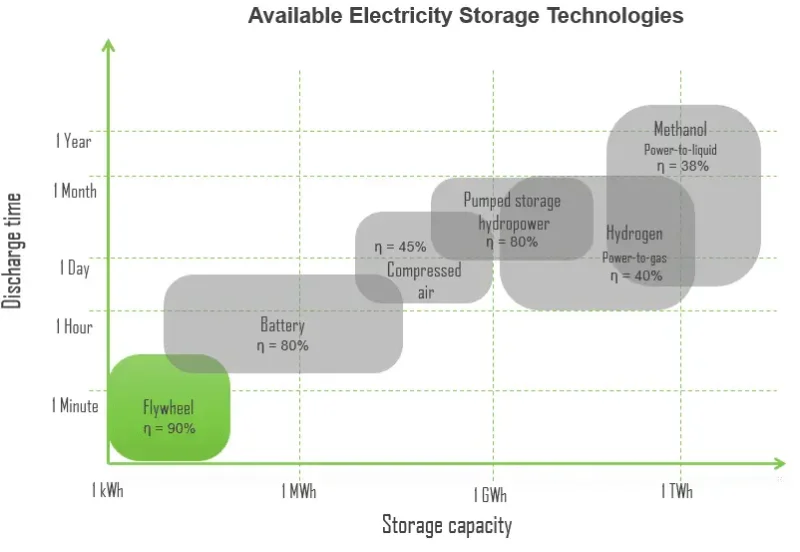

Or if switching the scale on the above graph into months or years, a system that enables long-term green energy storage, like a low-carbon alternative of the U.S. Strategic Petroleum Reserve.

Energy storage is growing

To address the renewable energy conundrum, green electricity storage capacity has been steadily growing and is expected to continue doing so.

Currently, pumped-storage hydro accounts for 90% of the total green electricity storage and is principally used to balance the grid’s daily demand variance shown earlier.

However, Li-based batteries for large-scale electricity storage are growing at the fastest rate, as their prices are rapidly plummeting due to the economies of scale, i.e. They’re used in virtually all portable electronics like smartphones, laptops and EVs.

Other storage solutions being explored include:

- Green hydrogen storage (long-term strategic storage, still in its early development).

- Sand batteries (season-term thermal storage, still at the conceptual stage)

- Concentrated Solar (Thermal energy storage, being trialled)

- Compressed-Air systems (Gradually scaling up).

- Gravity systems (Concept-stage)

There are too many concepts being explored to make a comprehensive list, yet there is one technology in particular that constantly evades much media attention yet is pretty much proven: flywheels.

What is a flywheel?

Flywheels store rotational energy using the physical principle of conservation of angular momentum.

In plain English, a flywheel is a heavy wheel that stores energy by rotating efficiently. The heavier this rotating wheel, and the less resistance it experiences, the more energy it can store for longer periods of time.

They’ve been in use for centuries, with a potter’s wheel being a typical example in antiquity and the giant flywheel used in an early Victorian locomotive pictured above.

Flywheels are now a ubiquitous piece of mechanical systems. For example, they’re used to store rotational energy in the transmission system of any manual road vehicle and are an integral part of regenerative braking systems.

Flywheels can absorb energy by rotating faster and release energy by giving away their rotation into something else.

Flywheel Energy Storage (FES)

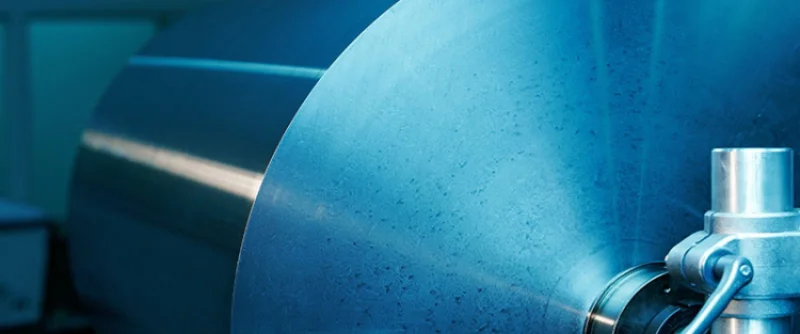

Flywheel Energy Storage (FES) systems refer to the contemporary rotor-flywheels that are being used across many industries to store mechanical or electrical energy.

Instead of using large iron wheels and ball bearings, advanced FES systems have rotors made of specialised high-strength materials suspended over frictionless magnetic bearings capable of spinning at 20,000 – 50,000 rpm (revolutions per minute).

A magnetic motor and electric generator are attached to the rotor in a dynamic system that can switch from charging to discharging within milliseconds. This is usually encased within a vacuum to reduce air resistance and close the system from contaminants that would result in wear and tear.

These unique properties give flywheel systems many advantages over other competing energy storage systems, particularly regarding performance, adaptability and longevity.

The merits of flywheels

Efficiency

Due to their simple design and frictionless characteristics, flywheel systems can reach very high efficiencies of 70-95%, where only a small fraction of the energy is lost during storage.

Only some chemical battery technologies and Molten Salt systems can approach similar efficiencies, while the widely used pumped-hydro (PHS) schemes remain within the 70-85% range.

Responsiveness

Flywheels can dynamically switch between charging and discharging within milliseconds, which is crucial for power stabilisation.

For example, critical manufacturing facilities, hospitals and data centres cannot afford power outages, and many rely on these systems to provide immediate power supply until a backup energy system can be deployed.

Once discharged, flywheels can immediately begin recharging for any eventuality and will generally take minutes to do so. Comparatively, all other green electricity storage technologies take hours to do so.

Also, the amount of energy stored can be accurately measured as it is directly proportional to rotation. This is not the case with storage with too much heterogeneity within its system, such as most chemical batteries (i.e. phone charge is never too accurate).

Considering the likely future where internet connections will be ubiquitous and automated algorithms will run smart grids smoothly, the fast response rates of FES will certainly come in handy, particularly when considering the complexities brought in by variable renewables.

Longevity

Longevity is particularly true in contemporary high-tech flywheels that use magnetic bearings. The systems in place today have an estimated lifetime of up to 100,000 charge/discharge cycles, but some estimate that this could be indefinite with due maintenance.

This is due to the lack of mechanical wear and tear of its components or unlikely material fatigue. For example, some 200-year-old showcase Victorian-age locomotives are still using their original iron-cast flywheels in present demonstrations.

Comparatively, Li-Ion batteries are known for degrading after a few thousand cycles, both in the amount of charge they can store and the power they can deliver. On the other hand, well-maintained pumped hydro schemes can also last for many decades yet depend on the availability of water to operate.

Adaptability

Being made of encased modules, these flywheel systems can be factory-made and deployed on any site, much like Li-Ion batteries.

Flywheels also have the advantage of operating at a larger range of temperatures compared to chemical batteries that lose capacity at both high and low temperatures.

FES systems can be installed on wind farm sites to remove any short-term shifts in weather patterns, within large data centre facilities to ensure a consistent and stable power supply or even on-site large physics experiments like JET.

In fact, flywheels are so adaptable that their use cases extend to most motorised vehicles (e.g. regenerative braking, gear shift systems), satellite energy storage, trams and trains, etc.

Since FES systems can be designed with as many individual flywheels as necessary, the power capacity can be adjusted simply by installing more or fewer units. More units can be added or removed at a later date depending on power requirements, similar to how nuclear micro-reactors and containerised solar energy operate.

Comparatively, pumped-hydro storage, CSP, molten salt and sand batteries are all static constructions, so massive there is no way of porting them if energy requirements change.

Low-carbon footprint

Flywheels are officially a green energy storage solution as there are no direct carbon emissions from their energy storage operation.

On top of this, FES systems don’t require major on-site construction or earthworks (which comes with its own carbon and water footprint), and since it’s not a chemical battery, it doesn’t require ‘controversial’ metals like Lithium or Lead that clearly have an overall negative socio-environmental impact.

Also, FES components are inert and often case recyclable. Considering these systems may operate indefinitely with little maintenance, any indirect emissions and byproduct waste are minimal over their operational lifespan.

We have not found any comprehensive life-cycle assessment comparisons between storage technologies, but we have compiled the following figures from the literature (figures assume storage charging is done via renewables):

| Storage Technology | Emissions (g CO2eq / kWh) | Source |

|---|---|---|

| Utility Flywheel (FES) | 5 - 30 | NREL |

| Residential Li batteries | 30 - 80 | Journal of Cleaner Production |

| Utility Li-Ion batteries | 70 - 300 | Forbes |

| Pumped Hydro Storage (PHS) | 20 - 80 | IEA |

| LNG (Gas) Storage | 500 - 1,000 | Natural Gas Vehicle Alliance |

These indicative figures show flywheels are one of the most attractive options for green energy storage in terms of their carbon footprint.

Proven tech

Unlike some much-hyped green energy storage solutions such as sand batteries and underground hydrogen storage, flywheel energy storage technology has been used for hundreds of years and is proven within its niches.

The downside of flywheels

So far, it seems like we should have covered the world with flywheels by yesteryear.

However, flywheels do have some key disadvantages when it comes to large-scale grid capacity storage, which is apparent from its lack of presence in this sector, predominantly covered by fossil fuel reserves and pumped hydro storage.

Limited capacity and discharge rate

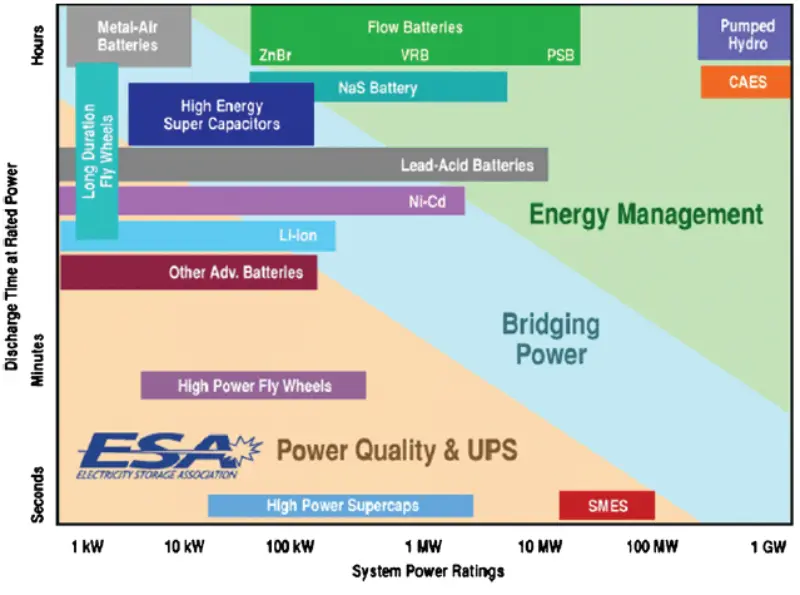

One of the main issues with FES systems is their low storage (MWh) capacity and low power (MW) capacity compared to other storage solutions.

Regulating large-scale infrastructure such as the national grid with the UK’s wind farms requires significant energy and power capacities that go into the thousands of megawatts. Only Pumped Hydro Storage and Compressed-Air Energy Storage can currently claim these energy management capabilities.

To put this energy and power gap into perspective, the largest pumped hydro schemes can store 10s of GWh of energy and deliver 1000s of MW over many hours, essentially enough to cover a total outage of a power station the size of Drax.

Comparatively, the largest 775-ton flywheel system in the world that is used to power JET can store 1MWh of energy and discharge up to 400MW for a couple of minutes.

This inability to scale in both capacity and discharge output has constrained the usability of flywheels to its principal use case as a rapid, short-term power stabiliser.

But, it’s not good enough for long-term, large-scale, green energy storage as simple and efficient as this clever mechanical system.

This can be more clearly understood from the chart below that categorises energy storage solutions based on their power capacities and responsiveness

Expensive

Flywheels are a very simple technology, but FES is high-tech and requires costly state-of-the-art manufacturing. Mass-producing FES systems is not possible at present, preventing it from leveraging economies of scale, like batteries.

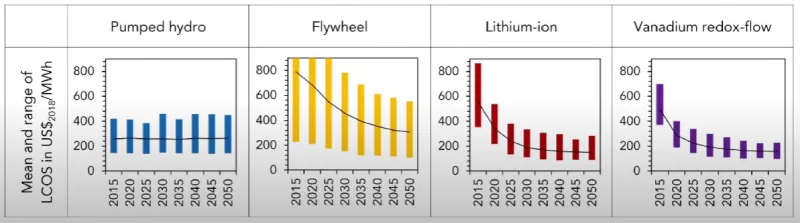

Also, LCOS (Levelised Cost of Storage) calculations that are an LCOE equivalent to energy storage don’t place flywheel favourably against other technologies.

This means that investors may generally favour other energy storage technologies as they remain cheaper than flywheels, except in flywheel’s own niche.

This begs the question, would economies of scale benefit the cost of these flywheels? We believe this can’t be dismissed given how motivated companies like Starlink and OneWeb have mass-produced telecommunication satellites with only a decade of development.

At the same time, improvements in superconductors are expected to make efficiency improvements to their magnet bearings, and the rapid innovation in material science means that stronger material may be available for faster rotation, i.e. more energy storage per unit.

Conclusion

Flywheel Energy Storage systems are impressive in almost all metrics.

They can be deployed anywhere, are extremely efficient and responsive and, best of all, have a very low carbon footprint, particularly considering that any units constructed may last indefinitely.

Flywheels are, without a doubt, kings of their small-scale, responsive energy storage niche, which is a less-discussed yet crucial part of the world’s electrification.

However, flywheels’ Achilles heel lies in their lack of total energy capacity and discharge time. They simply cannot replace fuels that hold energy within their atomic structure, like hydrogen or fossil fuels, or simply can’t remain locked in a reservoir until needed.

The energy crisis highlighted the urgent need for long-term green energy repositories that could last months, if not years, a role that the stockpiling of fossil fuels currently plays and one in which flywheels will be an unlikely player.

External Resources

- iea.org – Storage Growth

- DOE – Global Energy Storage Database

- Undecided with Matt Ferrell

- Genius Engineering

- New Mind

- Pinio

- Ourworldindata.org – Energy

- Elexon

- NY State

- Flywheel

- Zhang’s Research Group

- eesi.org

- sandia.gov

- Imperial College – LCOS

- Imperial College – Future cost of storage

- Joule (ScienceDirect) – Future of Flywheel

- Journal of Energy Storage – LCOS

- Applied Energy – LCOS

- energy.gov – PHS

- energydigital.com

- e-Prime

- Forbes

- NREL

- Journal of Cleaner Production

- Natural Gas Vehicle Alliance

- UMichigan

- Mergeflow

- BEIS

- nuclear-power

- Wired

- energy-storagenews

- Research Gate